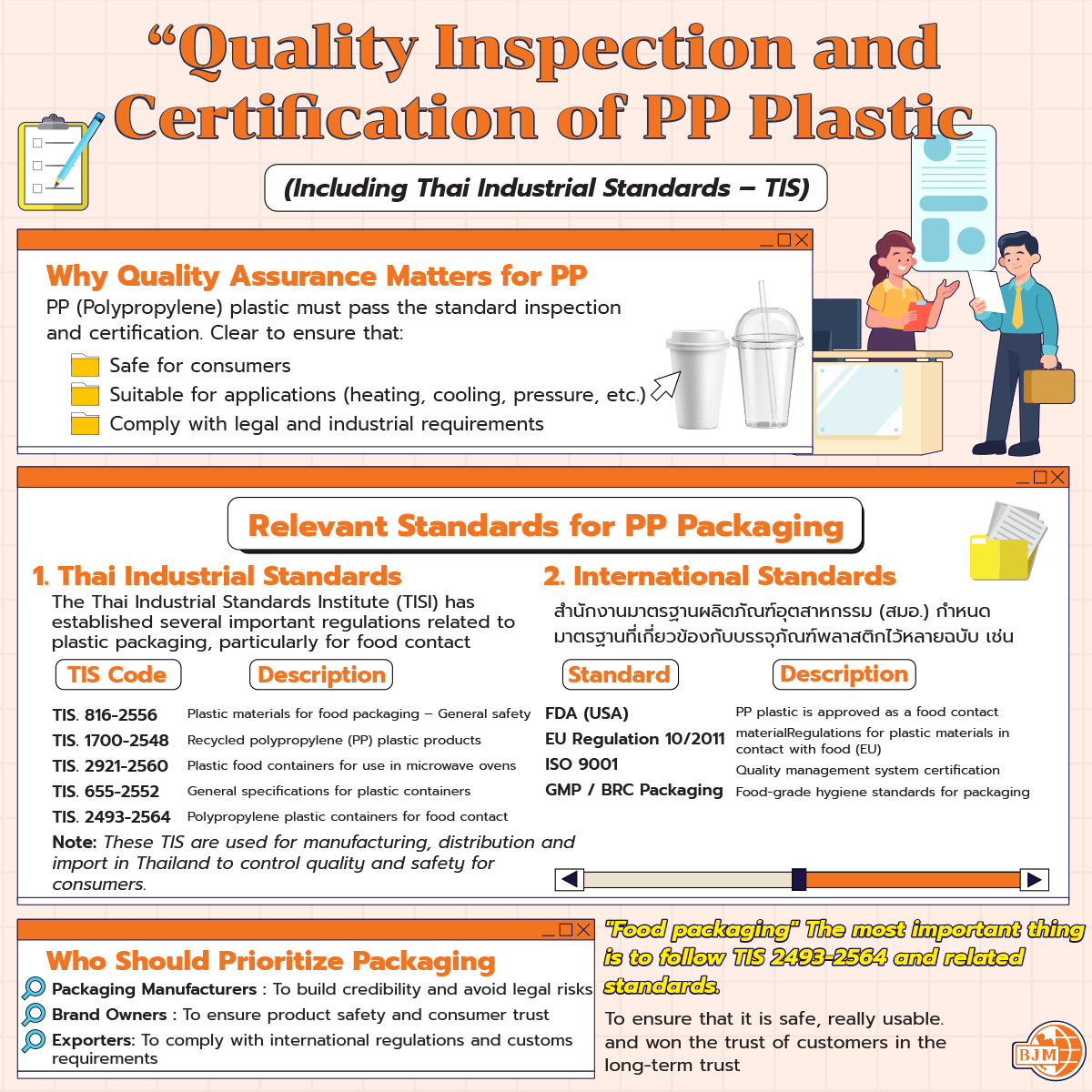

“Quality Inspection and Certification of PP Plastic Packaging” (Including Thai Industrial Standards – TIS)

Why Quality Assurance Matters for PP Packaging?

Polypropylene (PP) plastic is widely used in the packaging industry, especially for food containers, due to its heat resistance, safety, and durability. However, to ensure consumer protection and compliance with regulations, PP packaging must undergo proper quality inspections and certification.

Relevant Standards for PP Packaging

1. Thai Industrial Standards (TIS)

The Thai Industrial Standards Institute (TISI) has established several important regulations related to plastic packaging, particularly for food contact materials:

-

TIS CodeDescription

-

TIS 816-2556Plastic materials for food packaging – General safety

-

TIS 1700-2548Recycled polypropylene (PP) plastic products

-

TIS 2921-2560Plastic food containers for use in microwave ovens

-

TIS 655-2552General specifications for plastic containers

-

TIS 2493-2564Polypropylene plastic containers for food contact

This is a key standard that specifically governs the use of PP plastic for food packaging. It includes requirements for chemical migration, physical properties, and thermal resistance to ensure food safety.

TIS 2493 is considered the most essential standard for PP plastic packaging used in direct food contact in Thailand.2. International Standards

-

StandardDescription

-

FDA (USA)PP plastic is approved as a food contact material

-

EU Regulation 10/2011Regulations for plastic materials in contact with food (EU)

-

ISO 9001Quality management system certification

-

GMP / BRC PackagingFood-grade hygiene standards for packaging production

Typical Quality Inspection Process

-

StepDescription

-

Raw Material VerificationUse certified food-grade PP resin with Certificate of Analysis (COA)

-

Migration TestingEnsure no harmful substances leach into food

-

Physical TestingEvaluate thickness, sealing, heat resistance, and impact strength

-

QC SamplingQuality check for each production batch per ISO/GMP standards

-

DocumentationProvide TIS 2493 certification, Test Reports, COC, and Food Grade Certificates

Who Should Prioritize Packaging Certification?

- Packaging Manufacturers :– To build credibility and avoid legal risks

- Brand Owners : – To ensure product safety and consumer trust

- Exporters :– To comply with international regulations and customs requirements