In today’s fast-paced world, packaging plays a crucial role not only in protecting products but also in ensuring convenience and food safety for consumers. Among the many types of plastics used in the food and beverage industry, Polypropylene (PP) stands out as one of the most versatile materials. One of its greatest strengths is its ability to withstand both hot and cold temperatures, making it a preferred choice for manufacturers seeking efficient and flexible packaging solutions.

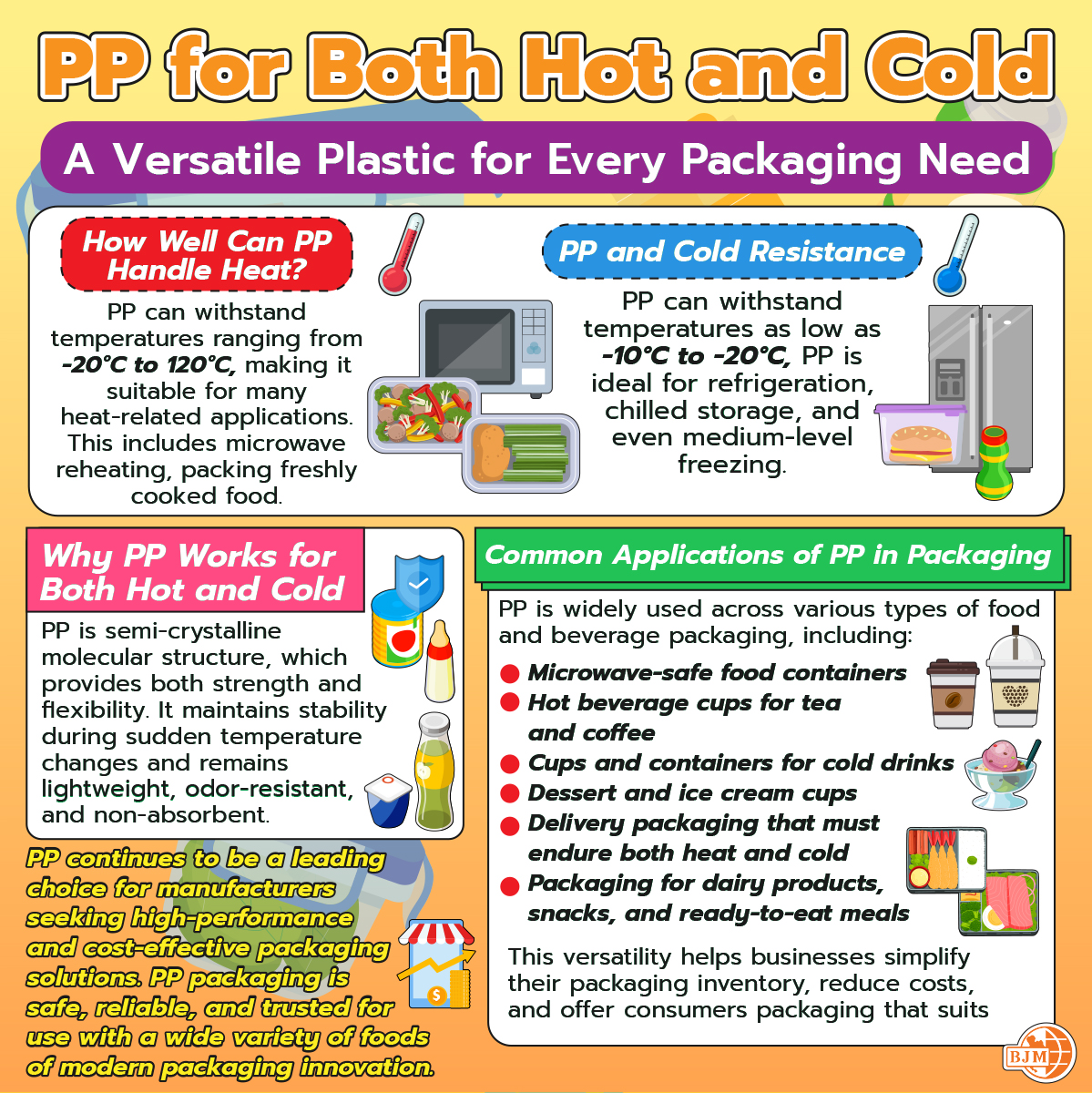

How Well Can PP Handle Heat?

A key reason PP is widely trusted is its excellent heat resistance. Typically, PP can withstand temperatures ranging from -20°C to 120°C, making it suitable for many heat-related applications. This includes microwave reheating, packing freshly cooked food, and even certain food-processing steps that involve mild heating such as steaming or light pasteurization.

The remarkable heat tolerance comes from the stable semi-crystalline structure of PP, which allows it to maintain its shape without distortion when exposed to heat. Importantly, PP does not release harmful substances when used correctly in food-contact applications, making it a safe option for consumers.

PP and Cold Resistance

In addition to heat resistance, PP also performs well under cold conditions. Withstanding temperatures as low as -10°C to -20°C, PP is ideal for refrigeration, chilled storage, and even medium-level freezing depending on the grade and formulation.

Unlike certain plastics that may become brittle or crack in cold environments, PP maintains its durability and flexibility. This makes it suitable for storing chilled desserts, beverages, ice cream cups, ready-to-eat meals, and many other cold-chain food products.

Why PP Works for Both Hot and Cold

The ability of PP to perform across a wide temperature range comes from its semi-crystalline molecular structure, which provides both strength and flexibility. It maintains stability during sudden temperature changes and remains lightweight, odor-resistant, and non-absorbent.

PP can also be produced in Food Grade quality that meets international standards such as FDA and EU food-contact regulations. This ensures that PP packaging is safe, reliable, and trusted for use with a wide variety of foods.

Common Applications of PP in Packaging

Because of its versatility, PP is widely used across various types of food and beverage packaging, including:

- Microwave-safe food containers

- Hot beverage cups for tea and coffee

- Cups and containers for cold drinks

- Dessert and ice cream cups

- Delivery packaging that must endure both heat and cold

- Packaging for dairy products, snacks, and ready-to-eat meals

This versatility helps businesses simplify their packaging inventory, reduce costs, and offer consumers packaging that suits modern lifestyles—lightweight, safe, and convenient.

PP remains one of the most dependable materials in the packaging industry due to its ability to withstand both hot and cold environments. With its strong structure, safe food-contact properties, and wide temperature resistance, PP continues to be a leading choice for manufacturers seeking high-performance and cost-effective packaging solutions.

As consumer expectations increase and the demand for convenient, multifunctional packaging grows, PP is set to remain at the forefront of modern packaging innovation.