When we talk about sustainability and carbon footprint reduction, most people may think of renewable energy, electric vehicles, or tree planting. Yet, packaging plays a surprisingly critical role in shaping the environmental impact of the entire supply chain. Among the various materials, Polypropylene (PP) has emerged as a strong candidate for driving meaningful change — proving itself to be not only functional and cost-efficient, but also environmentally responsible.

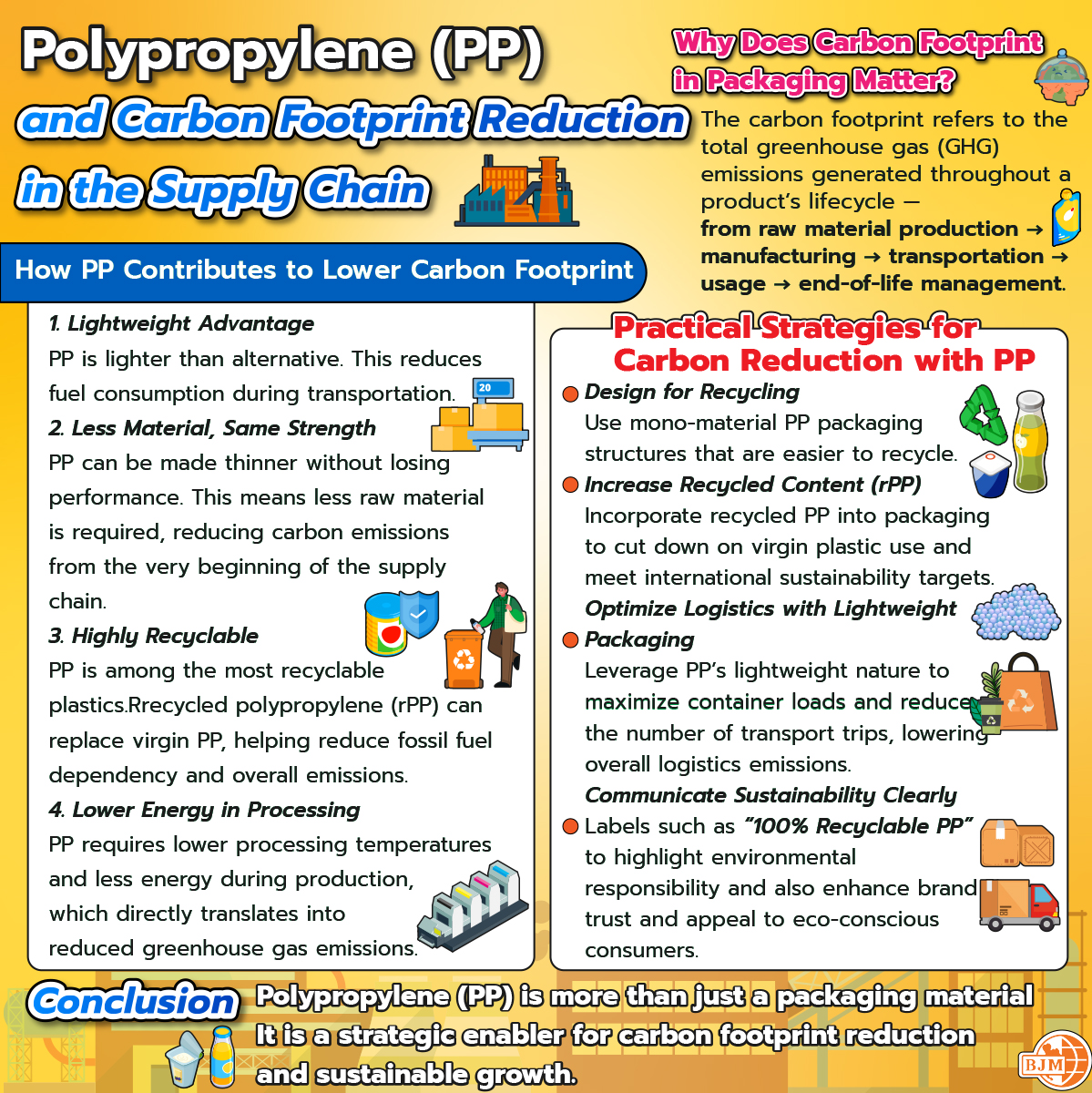

Why Does Carbon Footprint in Packaging Matter?

The carbon footprint refers to the total greenhouse gas (GHG) emissions generated throughout a product’s lifecycle — from raw material production → manufacturing → transportation → usage → end-of-life management.

In the packaging industry, choosing the wrong material or design could unnecessarily increase emissions and compromise a brand’s sustainability credentials. Today, with global brands, retailers, and consumers demanding greener solutions, the carbon footprint of packaging has become a key business concern.

How PP Contributes to Lower Carbon Footprint

- 1. Lightweight Advantage PP is lighter than alternative materials such as glass or metal. This reduces fuel consumption during transportation, enabling brands to ship more units per trip and significantly cut transport-related emissions.

- 2. Less Material, Same Strength Thanks to its strength and flexibility, PP can be made thinner without losing performance. This means less raw material is required, reducing carbon emissions from the very beginning of the supply chain.

- 3. Highly Recyclable PP is among the most recyclable plastics. With proper waste collection and sorting, recycled polypropylene (rPP) can replace virgin PP, helping reduce fossil fuel dependency and overall emissions.

- 4. Lower Energy in Processing Compared to PET or PVC, PP requires lower processing temperatures and less energy during production, which directly translates into reduced greenhouse gas emissions.

Practical Strategies for Carbon Reduction with PP

- Design for Recycling Use mono-material PP packaging structures that are easier to recycle, ensuring higher recovery rates and better quality recyclate.

- Increase Recycled Content (rPP) Incorporate recycled PP into packaging to cut down on virgin plastic use and meet international sustainability targets set by global retailers and FMCG brands.

- Optimize Logistics with Lightweight Packaging Leverage PP’s lightweight nature to maximize container loads and reduce the number of transport trips, lowering overall logistics emissions.

- Communicate Sustainability Clearly Labels such as “100% Recyclable PP” or “Made with Recycled PP” not only highlight environmental responsibility but also enhance brand trust and appeal to eco-conscious consumers.

From Packaging Choice to Brand Value

By adopting PP in packaging strategies, companies can:

- Reduce the carbon footprint across the entire supply chain

- Align with international sustainability regulations and partner requirements

- Strengthen consumer confidence and loyalty

- Elevate brand image as a sustainability leader

Conclusion

Polypropylene (PP) is more than just a packaging material — it is a strategic enabler for carbon footprint reduction and sustainable growth.

In today’s competitive market, where sustainability is as important as price and quality, leveraging PP in design, production, and post-use management helps brands move closer to Net Zero targets while actively contributing to a circular economy. 🌍♻️